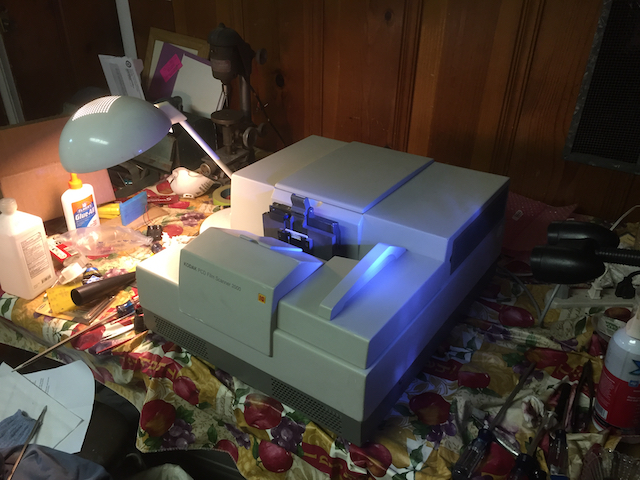

A few years ago I was able to run the k4050 plugin up to the point where it fails to detect any scanners on the SCSI bus as I have not connected the scanner to the SCSI.

Over the last few years I was given copies of the mac 8.6 software (diagnostics) the sun PIW installers, and recently the service manual. This made me take another look at the diagnostics program for mac os 8/9. The service manual was targeted to the Sun Piw. There is a lot of Piw code in the Photoshop plugin driver.

The main issue with the Mac os 8 diagnostic program was that it was zipped. This removed all the resource data effectively destroying the program. A Hex dump of the remaining part of the app shows it as PowerPC PEF built with mangled name symbols. This would imply that most of the app is still there and might be recovered by synthesizing the resource fork.

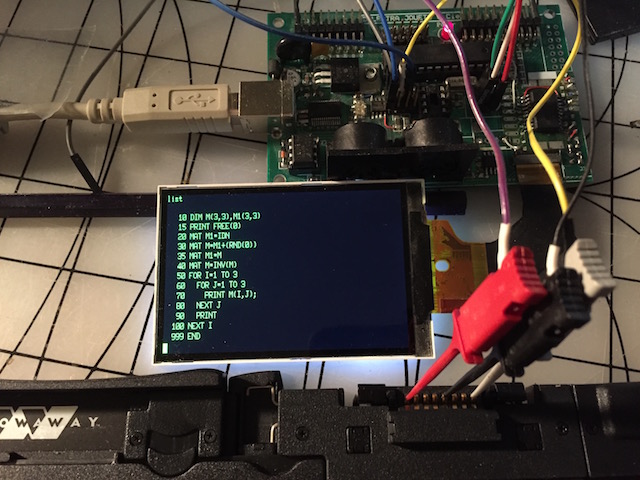

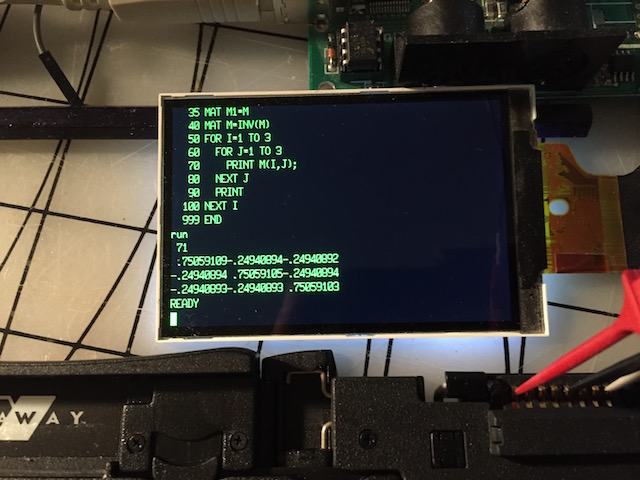

The same custom dissembler written for the photoshop plugin was used to dump the diagnostic. A search online found a copy of Metrowerks CodeWarrior that seems to match the libraries used. An example app was built and the resource skeleton was added to the resource fork. Type and creator set to application.

Of course the menus are incorrect and there are no windows. But the app runs. It even generates a debug log though the try/catch mechanism. Placing a breakpoint just before the ‘wrong scanner’ exit allows tracing. Time to read up on CodeWarrior PPob classes. The code also uses some Rouge Wave string classes. The PCD4050 plugin also uses this library (available from the Sun linux IDE.) That library has not been updated since 1996. Interesting to see that it has #ifdef definitions for MacOS and CodeWarrior.

Since these apps are compiled with debug tags with mangled names, it is almost easy to read the code. The code also used a try/catch error handler. This will sometimes even give the filename and line number of the source code. About 40 to 50 percent of the code is power-plant application framework. Given that many of the remaining classes start with Piw, this code is basically ported sun code.

The SCIS driver classes are preceded with DIS. I have been unable to find this class as a library. Most likely this was an in house library.

The diagnostic and calibration programs used special strips of film exposed with a test pattern. The manual gives the layout of these patches along with some YCC values of a set of patches that are different on a given target.

The Mac OS 8.6 zip archive contains a smi of a calibration run (and logs) these did not use resource forks. The smi will mount and is an image of the calibration floppy. The files in the system extensions folder seem flat and look to contain matrix data for a 4050 scanner.

The resulting tables give RGB values. Probably in volts. The upper ranges are over 2048. but quite a bit less than 4096. Scaling with a 4096 (2^12) results in the patches displaying really dark on the display. Inverting the RGB, and one can see washed out color patches.

It is probable that these calibration strips have all been lost or destroyed. There is no evidence any were ever online. Chances of finding them are slim to none. I suspect the handful of people who have contacted me represents most of those who may retain a slight interest in this obsolete tech.

In the meantime, here is a bit of an update as to what I have found and done.

Entering the logged result values into a simple postscript program shows this grid matches the Illustrations in the service manual. This is a way a calibration film strip could be made. If one could photograph the resulting postscript output then the results could be photographed onto film. I have not done film photography (other than with the stereo realist in years.)

With my searches for data relating to PhotoCD I know that old cameras are cheap and sold in bulk. A visit to the local electronics recycler has tubs of them. Mostly digital, but quite a few film cameras as well. Some even loaded with film. I knew I had an old can of expired film. All I would need to do would be to expose it with precisely placed color. patches. Something postscript can do. I purchased a dozen or so cameras. Some had film jammed inside.

I learned about something worse than photo CD. APS! How could I have missed APS and Advantix? Oh no, a totally new distraction. I now have half a dozen APS cameras. And a completely new distraction. I suspect there will be more on this later. These cameras are a world unto themselves. At the time of this blog writing, they can be had cheap and old film and processing remains available for others who like really failed products.

While these cameras are interesting, they do not take normal film. Sort of a film data tape hybrid. They do contain some interesting motors and gearing. This film is no longer manufactured. Some of the cameras contained partial rolls. I found that the local lab can process it.

I also found a school science project supplier online. Too bad I did not have access to this sort of thing 25 years ago. They sell simple spectrometers, filters and diffraction gratings. I got out my old copy stand and rigged it with LED lighting.

I used an old iPhone to simply photograph the filter slides. I then took the APS camera and shot the rest of the roll through each filter against my monitor background. The results are promising. The film came back and each frame has the inverse of the color. I have not attempted to scan the returned film as the Kodak scanner has a long way to go. The old USB scanner i have gives less than satisfactory results.

The next step is to modify an old Olympus film camera that I gutted. This was a point an shoot camera. A digital camera back would probably be more productive. This way is so much more interesting. An Arduino should be able to control the shutter solenoid and the film advance.

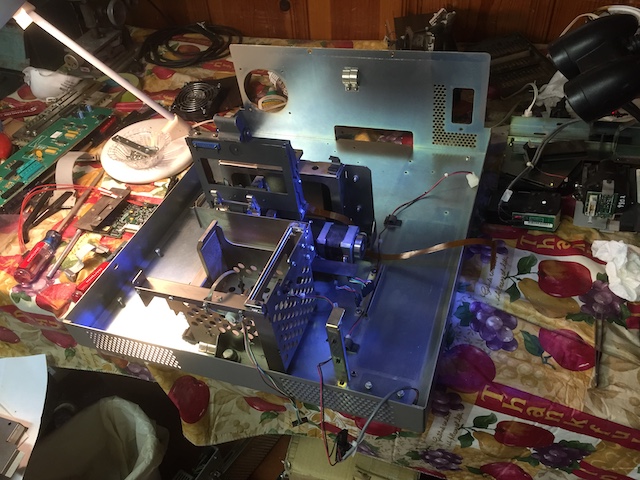

A lot of the work over the last couple of years has been dissembling and re-construction the plugin code. This sort of effort does not really lend itself into frequent blog postings. I sort of swap between dissembling camera hardware, and dissembling munged obsolete driver code. I also actively scan piano rolls with custom hardware. So these efforts do have some general use.

I have a couple of vintage macs which I use for tracing code. The plugin and the diagnostics are not small programs, with the plug in clocking in at near 2MB. The surviving diagnostic code is about half that size.

There was never a mac driver for the Film scanner 2000. I have not found any references to a DIS SCSI library. DIS is the class name of the SCSI library used. Other classes are PTS and PIW.

I would be really surprised if anyone has one of these units working anywhere. I check once a month for parts or more documentation. I think only three or so people ever contacted me. (but they all did have most useful stuff.)

I have also been hesitant to apply any power or signals to the SCSI port as I only have one film scanner. Research has directed to something called RaSCSI, which looks like a promising way to emulate the interface. This way I can also create a bridge to Ethernet, which would be a more practical way to communicate with the scanner.

I have yet to ring out an adapter to the MD50 connector from the HDI30 on the laptop. I did find I had a cable that goes to the flatbed Apple Color scanner which I still have. Another project for another blog.

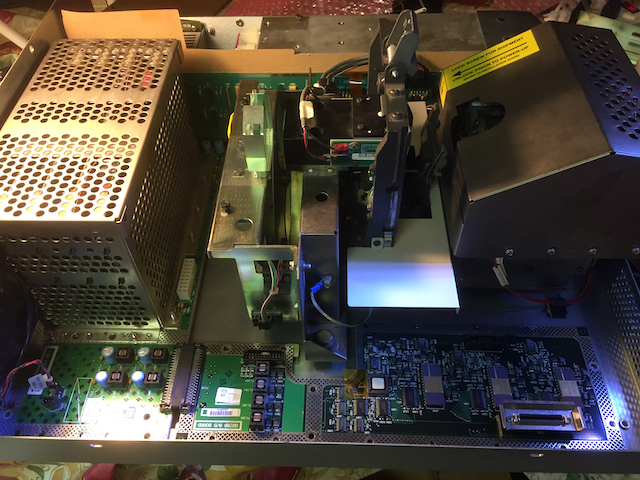

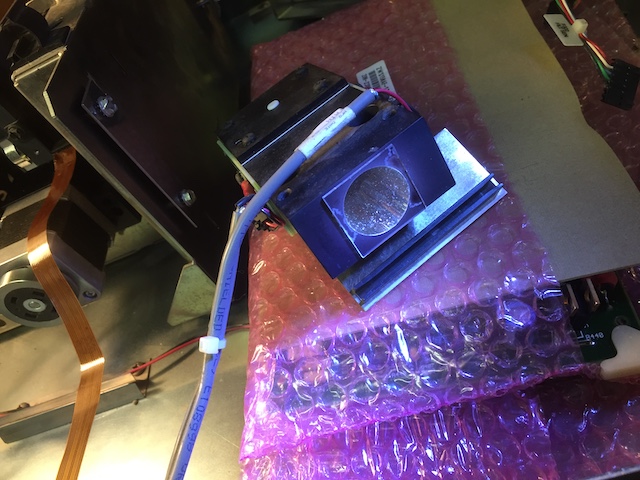

When the pcd 2000 scanner (or the other variations) are connected the host program downloads a hex file. While there is quite a sophisticated controller unit based on the 80C196KB. The actual program is downloaded every time.

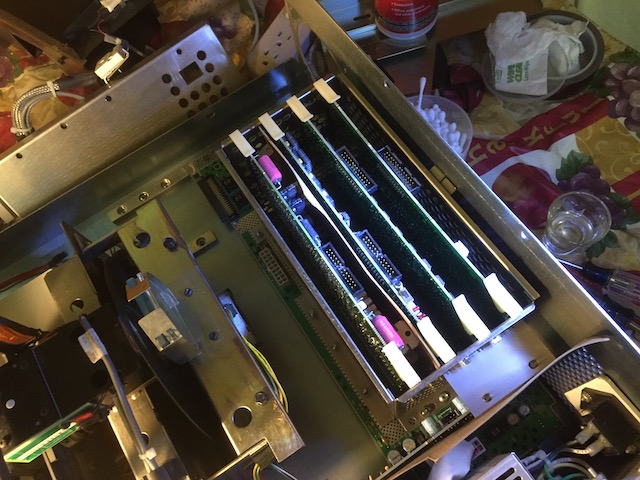

The service manuals are quite informative about this operation. There is also an online paper (which is behind a paywall) that also covers what these boards do. The heart of this system is an ASIC called a normalizer. This term is also used for programs that convert postscript to PDF. There must also be quite a bit of ram on this board as the raw images are 18megapixels. The user/operator is well protected from this raw data. It all seems to be about the density.

The mac OS 8 image does contain a hex file called 4050.hex While there are strings that refer to other scanners like the 2000, these are used in the wrong scanner dialog. Another reason I have not connected the scanner is the lack of the correct microcode file.

The PIW install disks contain more hex files. One is called scanner.hex and the other metaphor.hex. Dumping these shows the version strings. There are a lot of references to metaphor in the OS 8 code. It is almost it’s own class. Metaphor seems to be the 4045/4050 driver.

Scanner.hex is the 2000 code. I modified the postscript table driven disassembler that I have used on 8080, avr,m68k and powerpc to do 80C196. The first results were a bit off as I had used the wrong chip variant, which has different registers. When the 80C196 register table was used, the code started making sense.

The main processor board is mostly latches. There is some SRAM and a seven segment display. (this board is shown in an earlier blog.) An interesting thing is that the code regularly pushes 4 digit hex numbers onto the stack. These do not seem to be memory locations.

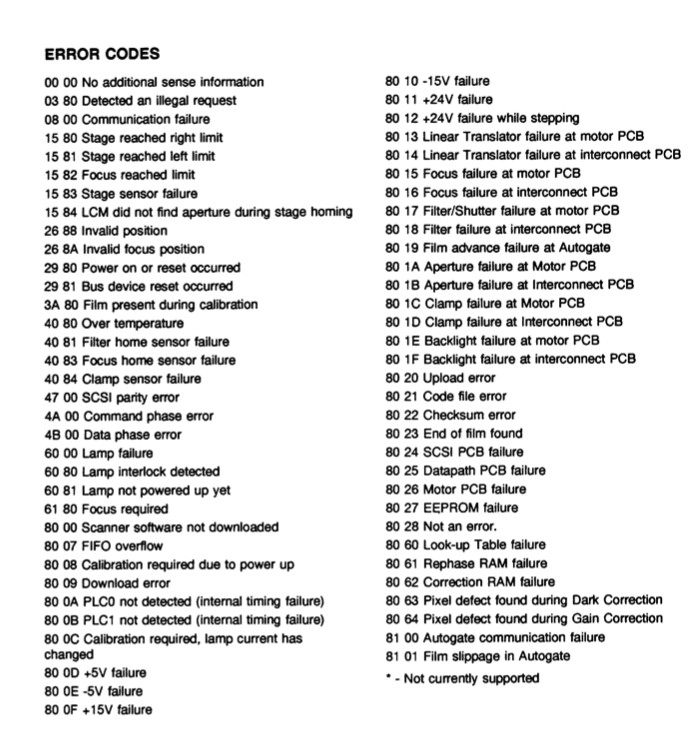

By chance I noticed that they were the same range as the error codes in the service manual. These codes should show on the 7 segment display. The sophistication of this is quite impressive. Too bad most consumer equipment does not do these types of boundary checks any more. I think they really did think this tech would last the next hundred years.

by adding these numbers to a table in the disassembler one can see the error handler. The timer overflow basically sets counters. So some sort of kernel is being used with the state queued.

D0 00C80B: C8E0 '..' prepError:PUSH .stack_frame. looks like error handler setup

C0 00C80D: A018E0 '...' LD .stack_frame.,SP ; .stack_frame. <- SP

C0 00C810: C8A6 '..' PUSH R.A6

C0 00C812: A3E0041C '....' LD AX,000004H[.stack_frame.] ; AX <- Var2

C0 00C816: 8981291C '..).' CMP AX,#0x2981 ; Bus device reset

C0 00C81A: D726 '.&' JNE L000016 ; PC <- 00C842 PC + 38 (00C81C)

D0 00C81C: C301560700 '..V..' L000017: ST ZERO_REG,000756H[ZERO_REG] ; .datamemL. MEM_WORD(000756) <- ZERO_REG

C0 00C821: 11A6 '..' CLRB R.A6

C0 00C823: 2018 ' .' SJMP L000018 ; PC <- 00C83D PC + 24 (00C825)

D0 00C825: ACA61C '...' L000019: LDBZE AX,R.A6 ; AX <- R.A6

C0 00C828: 09011C '...' SHL AX, #0x1

C0 00C82B: C71D460700 '..F..' STB ZERO_REG,000746H[AX] ; MEM_BYTE(AX + 1862) <- ZERO_REG

C0 00C830: ACA61C '...' LDBZE AX,R.A6 ; AX <- R.A6

C0 00C833: 09011C '...' SHL AX, #0x1

C0 00C836: C71D470700 '..G..' STB ZERO_REG,000747H[AX] ; MEM_BYTE(AX + 1863) <- ZERO_REG

C0 00C83B: 17A6 '..' INCB R.A6

D0 00C83D: 9908A6 '...' L000018: CMPB R.A6,#0x08 ; R.A6 == 8

C0 00C840: D3E3 '..' JNC L000019 ; PC <- 00C825 PC + -29 (00C842)

D0 00C842: A30156071C '..V..' L000016: LD AX,000756H[ZERO_REG] ; AX <- .datamemL. MEM_WORD(000756)

C0 00C847: 8907001C '....' CMP AX,#0x0007 ; AX == 7

C0 00C84B: DB2F './' JC L000020 ; PC <- 00C87C PC + 47 (00C84D)

D0 00C84D: 450400E01C 'E....' L000021: ADD AX,.stack_frame.,#0x0004 ; AX = .stack_frame. + 4

C0 00C852: C81C '..' PUSH AX

C0 00C854: A30156071C '..V..' LD AX,000756H[ZERO_REG] ; AX <- .datamemL. MEM_WORD(000756)

C0 00C859: 6107001C 'a...' AND AX,#0x0007 ; AX &= 7

C0 00C85D: 09011C '...' SHL AX, #0x1

C0 00C860: 6546071C 'eF..' ADD AX,#0x0746 ; AX += 1862

C0 00C864: C81C '..' PUSH AX

C0 00C866: EF6856 '.hV' LCALL L000022 ; (00C869 + 22120) -> 001ED1

C0 00C869: 65040018 'e...' ADD SP,#0x0004 ; SP += 4

C0 00C86D: A30156071C '..V..' LD AX,000756H[ZERO_REG] ; AX <- .datamemL. MEM_WORD(000756)

C0 00C872: 4501001C1E 'E....' ADD BX,AX,#0x0001 ; BX = AX + 1

C0 00C877: C30156071E '..V..' ST BX,000756H[ZERO_REG] ; .datamemL. MEM_WORD(000756) <- BX

D0 00C87C: A30156071C '..V..' L000020: LD AX,000756H[ZERO_REG] ; AX <- .datamemL. MEM_WORD(000756)

C0 00C881: 051C '..' DEC AX

C0 00C883: 6107001C 'a...' AND AX,#0x0007 ; AX &= 7

C0 00C887: CCA6 '..' POP R.A6

C0 00C889: CCE0 '..' POP .stack_frame.

C0 00C88B: F0 '.' RET

Some of the startup code is also of interest. Most likely the various communication sections are memory mapped in the higher address space. Curiously there is not a lot of windowing. This may be a result of the compiler used as only a subset of instructions are common.

L000003: SUB SP,#0x0004 ; SP -= 4

C0 00965B: C8E0 '..' PUSH .stack_frame.

C0 00965D: A018E0 '...' LD .stack_frame.,SP ; .stack_frame. <- SP

C0 009660: C872 '.r' PUSH R.72

C0 009662: C874 '.t' PUSH R.74

C0 009664: A100D072 '...r' LD R.72,#0xD000 ; R.72 <--12288

C0 009668: BD441C '.D.' LDBSE AX,#0x44 ; AX <-68

C0 00966B: C301E4001C '.....' ST AX,0000E4H[ZERO_REG] ; REG(R.E4) MEM_WORD(0000E4) <- AX

C0 009670: C2721C '.r.' ST [R.72],AX ; MEM_WORD(R.72) <- AX

C0 009673: A100D272 '...r' LD R.72,#0xD200 ; R.72 <--11776

C0 009677: A100801C '....' LD AX,#0x8000 ; Scanner software not downloaded

C0 00967B: C301E6001C '.....' ST AX,0000E6H[ZERO_REG] ; REG(R.E6) MEM_WORD(0000E6) <- AX

C0 009680: C2721C '.r.' ST [R.72],AX ; MEM_WORD(R.72) <- AX

C0 009683: A100D472 '...r' LD R.72,#0xD400 ; R.72 <--11264

C0 009687: C301E80000 '.....' ST ZERO_REG,0000E8H[ZERO_REG] ; REG(R.E8) MEM_WORD(0000E8) <- ZERO_REG

C0 00968C: A301E8001C '.....' LD AX,0000E8H[ZERO_REG] ; AX <- REG(R.E8) MEM_WORD(0000E8)

C0 009691: C2721C '.r.' ST [R.72],AX ; MEM_WORD(R.72) <- AX

C0 009694: A100D672 '...r' LD R.72,#0xD600 ; R.72 <--10752

C0 009698: C301EA0000 '.....' ST ZERO_REG,0000EAH[ZERO_REG] ; REG(R.EA) MEM_WORD(0000EA) <- ZERO_REG

C0 00969D: A301EA001C '.....' LD AX,0000EAH[ZERO_REG] ; AX <- REG(R.EA) MEM_WORD(0000EA)

C0 0096A2: C2721C '.r.' ST [R.72],AX ; MEM_WORD(R.72) <- AX

C0 0096A5: A100D872 '...r' LD R.72,#0xD800 ; R.72 <--10240

C0 0096A9: C301EC0000 '.....' ST ZERO_REG,0000ECH[ZERO_REG] ; REG(R.EC) MEM_WORD(0000EC) <- ZERO_REG

C0 0096AE: A301EC001C '.....' LD AX,0000ECH[ZERO_REG] ; AX <- REG(R.EC) MEM_WORD(0000EC)

C0 0096B3: C2721C '.r.' ST [R.72],AX ; MEM_WORD(R.72) <- AX

C0 0096B6: A100DA72 '...r' LD R.72,#0xDA00 ; R.72 <--9728

C0 0096BA: C301EE0000 '.....' ST ZERO_REG,0000EEH[ZERO_REG] ; REG(R.EE) MEM_WORD(0000EE) <- ZERO_REG

C0 0096BF: A301EE001C '.....' LD AX,0000EEH[ZERO_REG] ; AX <- REG(R.EE) MEM_WORD(0000EE)

C0 0096C4: C2721C '.r.' ST [R.72],AX ; MEM_WORD(R.72) <- AX

C0 0096C7: A120DC1C '. ..' LD AX,#0xDC20 ; AX <--9184

C0 0096CB: C3E0021C '....' ST AX,000002H[.stack_frame.] ; Var1 <- AX

C0 0096CF: B103CA '...' LDB R.CA,#0x03 ; R.CA <- 3

C0 0096D2: C61CCA '...' STB [AX],R.CA ; MEM_BYTE(AX) <- R.CA

C0 0096D5: A100DE72 '...r' LD R.72,#0xDE00 ; R.72 <--8704

C0 0096D9: C301F20000 '.....' ST ZERO_REG,0000F2H[ZERO_REG] ; REG(R.F2) MEM_WORD(0000F2) <- ZERO_REG

C0 0096DE: A301F2001C '.....' LD AX,0000F2H[ZERO_REG] ; AX <- REG(R.F2) MEM_WORD(0000F2)

C0 0096E3: C2721C '.r.' ST [R.72],AX ; MEM_WORD(R.72) <- AX

C0 0096E6: A301F2001C '.....' LD AX,0000F2H[ZERO_REG] ; AX <- REG(R.F2) MEM_WORD(0000F2)

C0 0096EB: 8100801C '....' OR AX,#0x8000 ; Scanner software not downloaded

C0 0096EF: C301F2001C '.....' ST AX,0000F2H[ZERO_REG] ; REG(R.F2) MEM_WORD(0000F2) <- AX

C0 0096F4: C2721C '.r.' ST [R.72],AX ; MEM_WORD(R.72) <- AX

C0 0096F7: A1401F1C '.@..' LD AX,#0x1F40 ; AX <-8000

C0 0096FB: C30122051C '.."..' ST AX,000522H[ZERO_REG] ; .datamemL. MEM_WORD(000522) <- AX

C0 009700: B11003 '...' LDB AD_RESULT_H,#0x10 ; AD_RESULT_H <- 16

C0 009703: B11015 '...' LDB IOS0,#0x10 ; IOS0 <- 16

C0 009706: B12616 '.&.' LDB IOS1,#0x26 ; IOS1 <- 38

C0 009709: B1010B '...' LDB TiMER1.H,#0x01 ; TiMER1.H <- 1

C0 00970C: B1260E '.&.' LDB IOPORT0,#0x26 ; IOPORT0 <- 38

C0 00970F: B1800E '...' LDB IOPORT0,#0x80 ; IOPORT0 <- 128

C0 009712: B10D11 '...' LDB SP_STAT,#0x0D ; SP_STAT <- 13

C0 009715: 910508 '...' ORB INT_MASK,#0x05 ; INT_MASK |= 5

C0 009718: 911213 '...' ORB INT_MASK1,#0x12 ; INT_MASK1 |= 18

C0 00971B: 11CF '..' CLRB R.CF

C0 00971D: 11D0 '..' CLRB R.D0

C0 00971F: 11CE '..' CLRB R.CE

C0 009721: B1201C '. .' LDB AX,#0x20 ; AX <- 32

C0 009724: C70175061C '..u..' STB AX,000675H[ZERO_REG] ; .datamemL. MEM_BYTE(000675) <- AX

C0 009729: B101D1 '...' LDB R.D1,#0x01 ; R.D1 <- 1

C0 00972C: C701A10B00 '.....' STB ZERO_REG,000BA1H[ZERO_REG] ; .datamemL. MEM_BYTE(000BA1) <- ZERO_REG

C0 009731: EF5831 '.X1' LCALL L000004 ; (009734 + 12632) -> 00C88C

C0 009734: EFA331 '..1' LCALL L000012 ; (009737 + 12707) -> 00C8DA

C0 009737: C701E30000 '.....' STB ZERO_REG,0000E3H[ZERO_REG] ; REG(R.E3) MEM_BYTE(0000E3) <- ZERO_REG

C0 00973C: EFAE88 '...' LCALL L000013 ; (00973F + -30546) -> 001FED

C0 00973F: 9BE00800 '....' CMPB ZERO_REG,000008H[.stack_frame.] ; Var4 == ZERO_REG

C0 009743: D730 '.0' JNE L000014 ; PC <- 009775 PC + 48 (009745)

D0 009745: C98029 '..)' L000015: PUSH #0x2980 ; Power on or reset occurred

C0 009748: EFC030 '..0' LCALL prepError ; (00974B + 12480) -> 00C80B

C0 00974B: 65020018 'e...' ADD SP,#0x0002 ; SP += 2

C0 00974F: 51080F1C 'Q...' ANDB AX,IOPORT1,#0x08 ; AX = IOPORT1 & 8

C0 009753: 99081C '...' CMPB AX,#0x08 ; AX == 8

C0 009756: D70A '..' JNE L002049 ; PC <- 009762 PC + 10 (009758)

D0 009758: C90080 '...' L002050: PUSH #0x8000 ; Scanner software not downloaded

C0 00975B: EFAD30 '..0' LCALL prepError ; (00975E + 12461) -> 00C80B .processed.

C0 00975E: 65020018 'e...' ADD SP,#0x0002 ; SP += 2

D0 009762: C90600 '...' L002049: PUSH #0x0006 ; MEM_WORD(SP -= 2) <- 6

C0 009765: EF7831 '.x1' LCALL L000132 ; (009768 + 12664) -> 00C8E0 .processed.

C0 009768: 65020018 'e...' ADD SP,#0x0002 ; SP += 2

C0 00976C: C701690600 '..i..' STB ZERO_REG,000669H[ZERO_REG] ; .datamemL. MEM_BYTE(000669) <- ZERO_REG

C0 009771: A1401FB8 '.@..' LD R.B8,#0x1F40 ; R.B8 <-8000

D0 009775: C800 '..' L000014: PUSH ZERO_REG

C0 009777: C800 '..' PUSH ZERO_REG

C0 009779: EFEC2A '..*' LCALL L000023 ; (00977C + 10988) -> 00C268

C0 00977C: 65040018 'e...' ADD SP,#0x0004 ; SP += 4

C0 009780: C800 '..' PUSH ZERO_REG

C0 009782: C800 '..' PUSH ZERO_REG

C0 009784: EFE12A '..*' LCALL L000023 ; (009787 + 10977) -> 00C268 .processed.

C0 009787: 65040018 'e...' ADD SP,#0x0004 ; SP += 4

C0 00978B: C95C7C '.\|' PUSH #0x7C5C ; MEM_WORD(SP -= 2) <- 31836

C0 00978E: C9785C '.x\' PUSH #0x5C78 ; MEM_WORD(SP -= 2) <- 23672

C0 009791: EFD42A '..*' LCALL L000023 ; (009794 + 10964) -> 00C268 .processed.

C0 009794: 65040018 'e...' ADD SP,#0x0004 ; SP += 4

C0 009798: C701680600 '..h..' STB ZERO_REG,000668H[ZERO_REG] ; .datamemL. MEM_BYTE(000668) <- ZERO_REG

C0 00979D: C90100 '...' PUSH #0x0001 ; MEM_WORD(SP -= 2) <- 1

C0 0097A0: EF53F5 '.S.' LCALL L000034 ; (0097A3 + -2733) -> 008CF6

C0 0097A3: 65020018 'e...' ADD SP,#0x0002 ; SP += 2

C0 0097A7: EFC2F5 '...' LCALL L000040 ; (0097AA + -2622) -> 008D6C

C0 0097AA: C701440600 '..D..' STB ZERO_REG,000644H[ZERO_REG] ; .datamemL. MEM_BYTE(000644) <- ZERO_REG

C0 0097AF: C701740600 '..t..' STB ZERO_REG,000674H[ZERO_REG] ; .datamemL. MEM_BYTE(000674) <- ZERO_REG

C0 0097B4: EF5A18 '.Z.' LCALL L000050 ; (0097B7 + 6234) -> 00B011

C0 0097B7: 881C00 '...' CMP ZERO_REG,AX ; ZERO_REG == AX

C0 0097BA: DF0A '..' JE L001816 ; PC <- 0097C6 PC + 10 (0097BC)

D0 0097BC: C92780 '.'.' L001817: PUSH #0x8027 ; EEPROM failure

C0 0097BF: EF4930 '.I0' LCALL prepError ; (0097C2 + 12361) -> 00C80B .processed.

C0 0097C2: 65020018 'e...' ADD SP,#0x0002 ; SP += 2

D0 0097C6: C800 '..' L001816: PUSH ZERO_REG

C0 0097C8: C90400 '...' PUSH #0x0004 ; MEM_WORD(SP -= 2) <- 4

C0 0097CB: EF467F '.F' LCALL L000107 ; (0097CE + 32582) -> 001714 .processed.

C0 0097CE: 65040018 'e...' ADD SP,#0x0004 ; SP += 4

C0 0097D2: C96008 '.`.' PUSH #0x0860 ; MEM_WORD(SP -= 2) <- 2144

C0 0097D5: C800 '..' PUSH ZERO_REG

C0 0097D7: EF4A79 '.Jy' LCALL L000887 ; (0097DA + 31050) -> 001124 .processed.

C0 0097DA: 65040018 'e...' ADD SP,#0x0004 ; SP += 4

C0 0097DE: C9D007 '...' PUSH #0x07D0 ; MEM_WORD(SP -= 2) <- 2000

C0 0097E1: C90200 '...' PUSH #0x0002 ; MEM_WORD(SP -= 2) <- 2

C0 0097E4: EF3D79 '.=y' LCALL L000887 ; (0097E7 + 31037) -> 001124 .processed.

C0 0097E7: 65040018 'e...' ADD SP,#0x0004 ; SP += 4

... < many lines of code skipped > ...Changing some of the data skip tables to disassemble the metaphor.hex and 4050.hex Shows that they have the same code and error messages. The 4050.hex that is with the munged mac disk image is quite a bit larger. It looks like there were many revisions. It is also probable that this code is a bit buggy when stressed outside the normal usage patterns.

In summery it looks like the calibration system can be re constructed through postscript and sacrificing old cameras to expose film. It is also possible to access the tables inside the programs as the films and calibration values will have shifted over the decades.

I have kept the pcdscan email address open. So feedback to that email at this domain is welcome. Perhaps someone does still have a working disk image of an installed system with the resource forks intact …